USED OIL ANALYSIS

To see an example of sample report, please click here

Used Oil Analysis reflects:

Categories of used oils analyzed:

Oil analysis is essential for assessing the health of equipment operation.

A sample of oil provides crucial information that can help:

-

Increase productivity

-

Reduce unscheduled downtime

-

Improve equipment durability

-

Lessen lubricant consumption

-

Assess condition of the oil

-

Evaluate condition of the equipment

-

Improve the environment in which the equipment operates

-

Overall, save money and time

-

4-stroke engine oils

-

CODA (2-stroke engines oils)

-

Hydraulic oils

-

Turbine oils

-

Gear oils

-

Thermal oils

-

Other types of industrial oils

Routine tests :

Viscometrics

-

Kinematic Viscosity @100°C & @40°C i.a.w. ASTM D7042

-

Viscosity Index i.a.w. ASTM D2270

Increase of Viscosity:

-

Oxidation

-

High Contamination (wear metals /soot)

Decrease of Viscosity:

-

Oil Consumption

-

Fuel Dilution

-

VM Degradation

Total Base Number – TBN:

-

ASTM D 2896

-

Monitor the remaining alkalinity of over based detergent additives

Increase of TBN:

-

Oil Consumption

-

High Temperature

-

Too low Viscosity

Decrease of TBN:

-

Fuel Dilution

-

Fuel Quality

-

Too long drain period

Total Acid Number – TAN:

-

ASTM D 664

-

Monitor the oxidative degradation of an oil.

Increase of TAN:

-

Oil degradation

-

High acid concentration in oil

Flash Point:

-

ASTM D 93

-

Detects flashpoint of lubricant

-

Lubricants are estimated to have a flashpoint above 190 °C

Decrease of flashpoint:

-

It’s possible that there is a fuel leak.

Water Content:

-

ASTM D 6304

-

Determination of water content in lubricants

Increase of water content:

-

Indicates that there is water inflow in the system.

ICP – OES:

Wear Metals / Contamination:

-

Iron

-

Chromium

-

Lead

-

Copper

-

Tin

-

Aluminum

-

Nickel

-

Silver

-

Silicon

-

Sodium

-

Vanadium

-

Cadmium

-

Lithium

-

Manganese

-

Titanium

ED – XRF :

Additive metals:

-

Phosphorus

-

Calcium

-

Zinc

-

Molybdenum

-

Magnesium

-

Barium

-

Sulfur

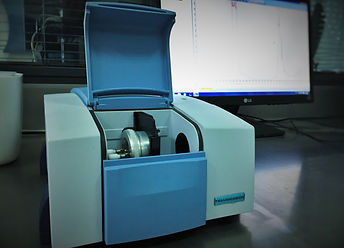

Infrared Spectrometry FT – IR:

-

Nitration: Premature thickening of the engine oil (natural gas engines)

-

Sulphation: Increased viscosity and varnish, sludge, sedimentation

-

Oxidation: See corrosion in machinery parts in high concentrations

-

Soot Content: Severe engine wear